About

Experience and Innovation Working for You

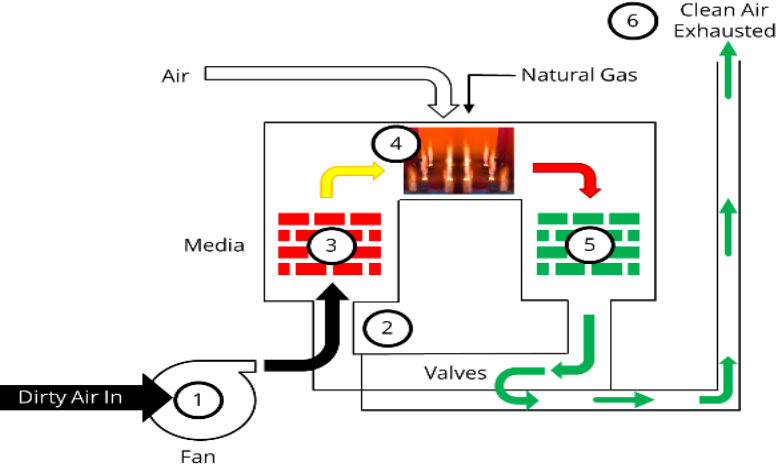

Environmental Control Systems: 30+ Years of experience in the environmental air pollution industry providing regional management, project management, installation, commissioning, controls design engineering, commissioning, operations, inspections, and maintenance for fluidized bed concentrators (FBC), regenerative thermal oxidizers (RTO), direct fired thermal oxidizers (DFTO), wet gas scrubbers, and dust collectors.

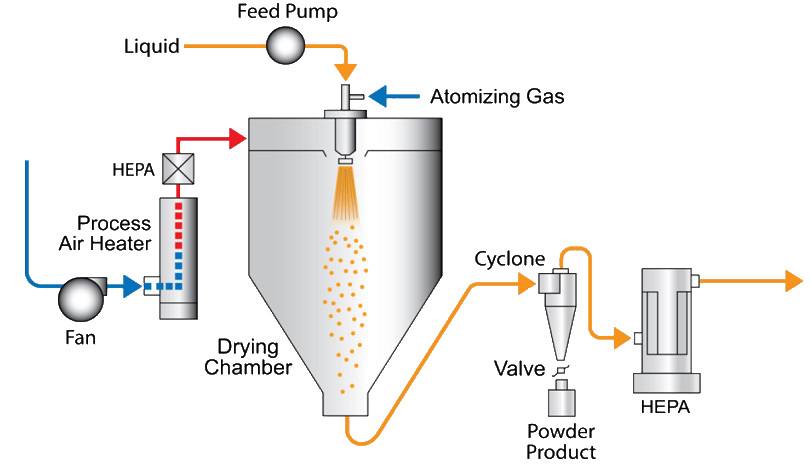

Spray Drying: 15+ Years of experience in the custom spray drying industry providing complete facility builds and operations, design, engineering, project management, and commissioning of a state-of-the-art spray drying systems. Became an integral part of the management team to operate and expand capabilities. Currently involved with the design, project management, installation and commissioning of two (2) commercial spry drying suites and warehouse expansion.

Operations Excellence: 30+ Years of experience supporting multiple industrial customers while maintaining, modifying, and improving production line equipment to meet environmental compliance needs and streamline operations.

Awards

Green Chemistry Challenge Award Winner from the Environmental Protection Agency (EPA)

Awards: JS Technical Services provided essential services for the demonstration that enabled the Green Chemistry Challenge Award from the Environmental Protection Agency (EPA). The EPA awarded their prestigious award to the “Chemical Adsorption Innovation that Reduces Emissions”, the CAIRE™ Technology. This pollution control capture technology drives down operating costs via energy use reductions, provides revenue via sales of captured turpentine, and reduces greenhouse gas emissions via reductions in natural gas usage. This recognition along with selection by the Department of Energy to negotiate the $2 Million Award to demonstrate the CAIRE™ Technology provides the platform to take this clean technology onto the commercialization pathway and into the marketplace.

“We’re very proud of the EPA award and its recognition of the value of the CAIRE™ Technology,” Starek said. “This innovation captures carbon from the air and provides key raw materials for biofuels, flavors, fragrances, and more. It is both economically and environmentally advantageous.”

Expertise:

Fluidized Bed Concentrator Systems

Regenerative Thermal Oxidizer Systems

Spray Drying Systems

Projects

|

Industry:

|

Wood Products Manufacturing

|

|

System:

|

Fluidized Bed Concentrator Pilot Unit

|

|

Location:

|

Florida

|

|

Description:

|

Provided project management, design, procurement, assembly, installation, commissioning, and aftermarket support for Fluidized Bed Concentrator. System provided >90% volatile organic compound reduction efficiency and captured high quality turpentine (terpenes).

|

|

|

Industry:

|

Automotive (paint)

|

|

System:

|

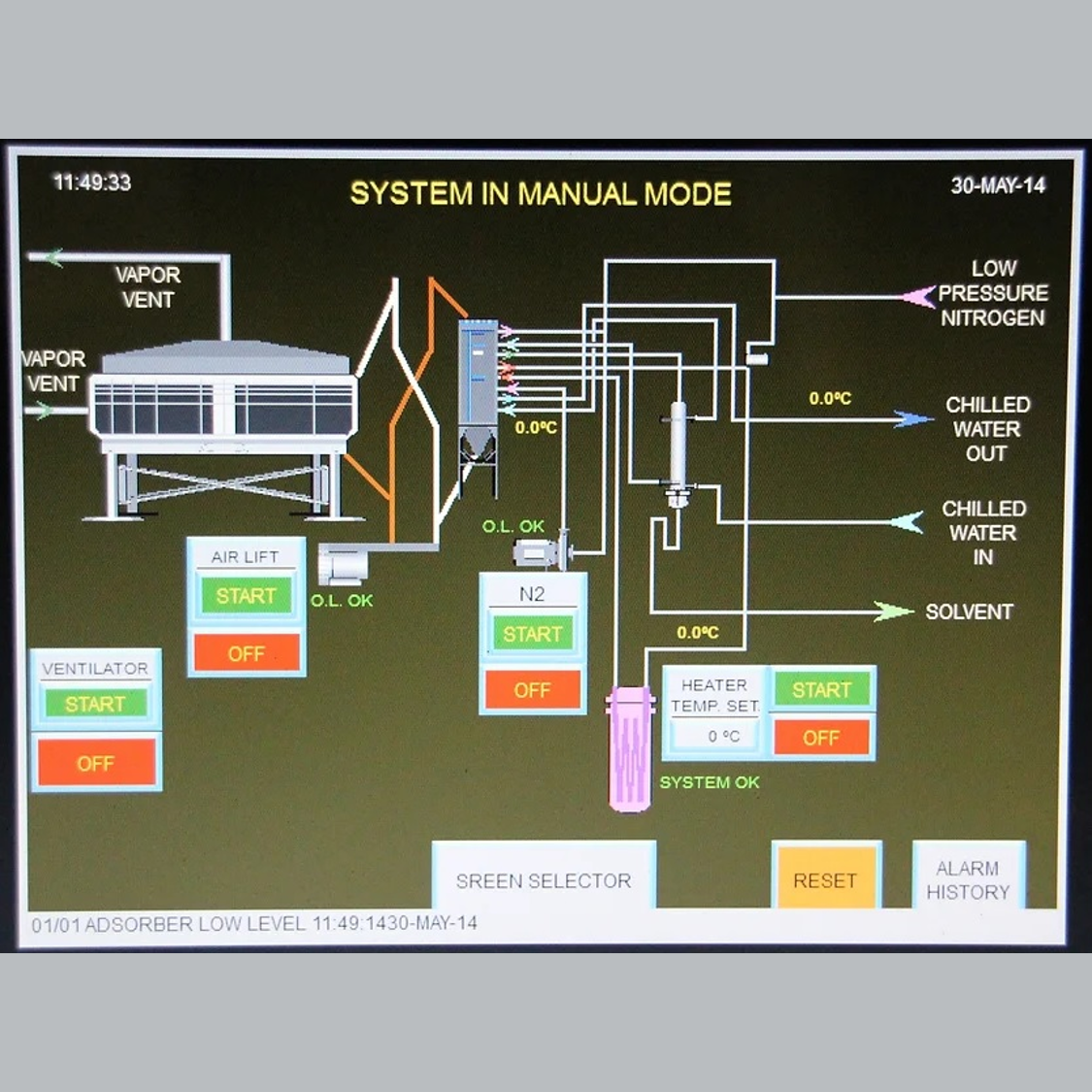

Program Logic Control (PLC) and Human Machine Interface (HMI) system for a 50,000 Cubic Feet per Minute (CFM) Fluidized Bed Concentrator solvent recovery system

|

|

Location:

|

China

|

|

Description:

|

Provided Program Logic Control (PLC) and Human Machine Interface (HMI) system for complete operation either in manual or automatic mode. Features included local and remote monitoring and control, safety interlocks, complete data log and display of all alarms, temperatures, and pressures. Instrumentation included oxygen level monitoring, temperatures, pressures, etc.

|

|

|

Industry:

|

Ingredients Supplier

|

|

System:

|

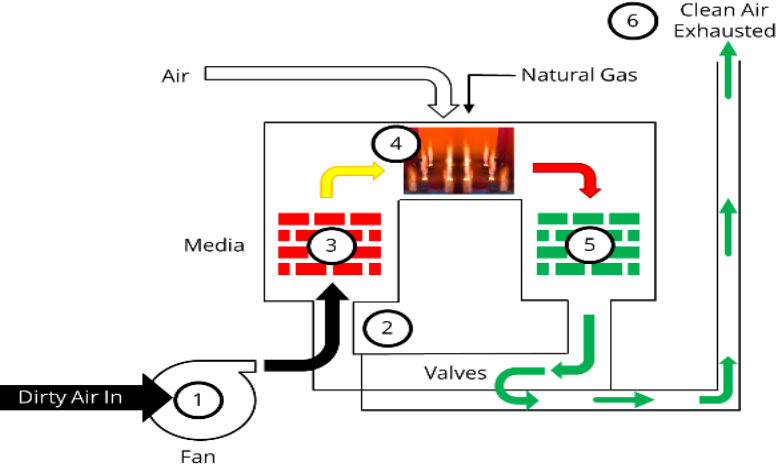

3-Can Regenerative Thermal Oxidizer (RTO)

|

|

Location:

|

New Jersey

|

|

Description:

|

Relocated and reinstalled complete regenerative thermal oxidizer system. Designed and installed all effluent ductwork. System has been installed and in compliance for 12+ years.

|

|

|

Industry:

|

Custom Tolling Manufacture

|

|

System:

|

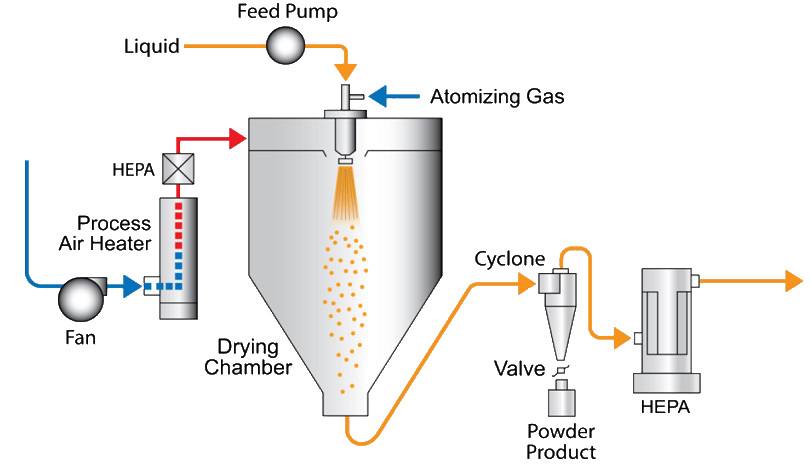

14’ Flatbottom Spray Dry Tower

|

|

Location:

|

New Jersey

|

|

Description:

|

Designed, provided project management, installed, and commissioned custom 10’ and 14’ diameter spray drying towers with 99%+ recovery efficiency.

|

|

|

Industry:

|

Metal Food Packaging

|

|

System:

|

Regenerative Thermal Oxidizer (RTO) Media Upgrade

|

|

Location:

|

Multiple Nationwide

|

|

Description:

|

Completed oxidizer media support bed retrofits. Custom designed media blends to handle high siloxane loadings. Provided project design and management, installation, commissioning, and routine maintenance to support 24/7 operations.

|

|

|

Industry:

|

Multiple, i.e. automotive, wood, electrical, chemicals, printing, waste handling, etc.

|

|

System:

|

Fluidized Bed Concentrator (FBC) Pilot Test System

|

|

Location:

|

Nationwide

|

|

Description:

|

This pilot unit is available and capable of treating a slip stream of process air effluent to ensure the highest capture and control capability of Fluid Bed Concentrator system. System is available to be dismantled, relocated, and set up at any site across the United States. Phase II commercial size unit will eliminate need for thermal oxidizers, reduce utility (energy) costs, and reduce greenhouse gas emissions.

|

|

Technology

Fluidized Bed Concentrator (FBC) Environmental Control Technology

How it Works

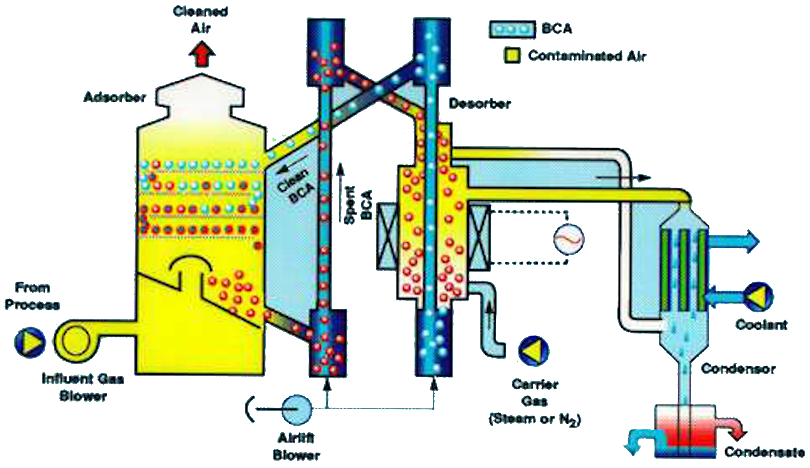

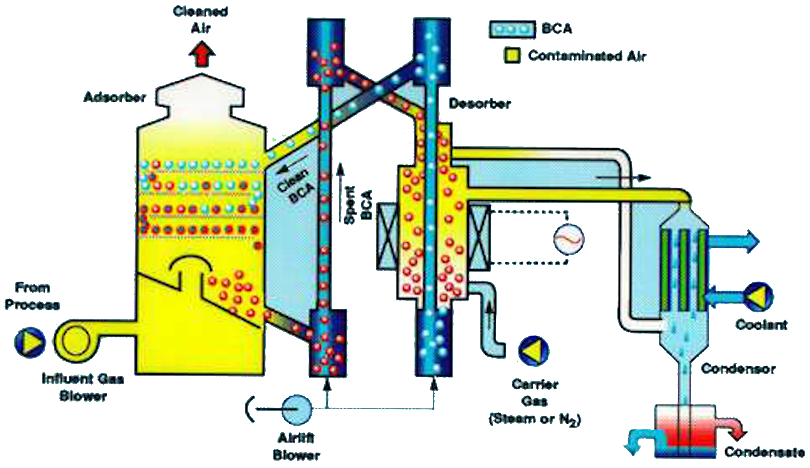

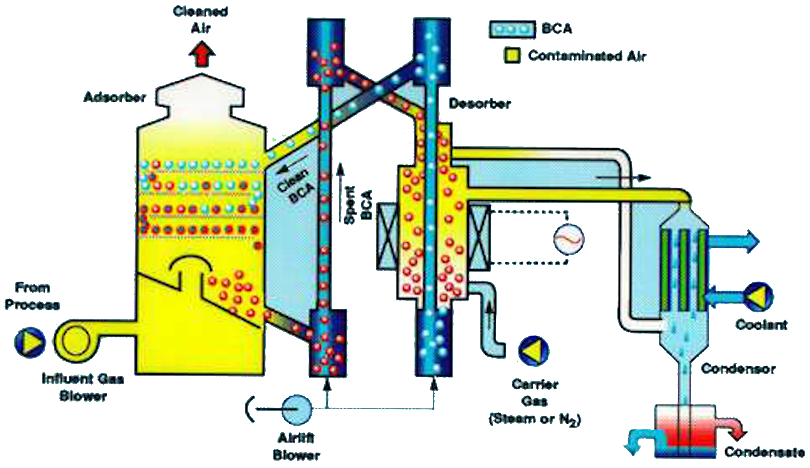

The adsorber section of the fluidized bed concentrator system includes a series of perforated plate adsorption trays. Contaminated process exhaust enters from the bottom, passing upward through the adsorption trays, fluidizing the adsorbent and adsorbing the Volatile Organic Compounds (VOCs). VOC saturated adsorbent flows to the bottom of the adsorber vessel, from which it is removed at a slow, steady rate and transferred to the desorber. Meanwhile, regenerated adsorbent is continuously fed into the top of the adsorber vessel, providing counter-current VOC removal.

In the desorber, the temperature of the adsorbent material is increased, causing it to release the VOC contaminants into a low volume, inert carrier gas stream. The cleaned adsorbent material is then returned to the top of the adsorber vessel for reuse.

The concentrated contaminant stream is so small that it can often be easily treated with a simple afterburner or recovered for reuse or disposal through condensation. The condensation process is shown below.

One key to achieving high performance levels is the beaded activated carbon adsorbent material. The small, spherical “beads” have a high surface area for adsorption and are ideal for treating a wide range of solvents at high or high concentrations. With an attrition rate of less than 1% per year, operating and maintenance costs are extremely low.

Leadership Team

JS Technical Services LLC and its affiliates have provided project management, procurement, engineering design, commissioning, and maintenance for numerous systems thru 28-countries and 46 of the contiguous United States.

James Starek

Owner, Director, Project Engineering Lead

Owner of JS Technical Services. 20+ Years of engineering and consulting experience in the environmental air pollution industry. Extensive experience in fabrication design, instrumentation, controls, and electrical systems. Provides engineering support for Fluidized Bed Concentrator design, fabrication, installation, commissioning, operations, and compliance testing. University of Maryland. Air Force. Electronic Systems Technology Degree.

Matt Lachenmayr

Operations and Installation Lead

30+ years of operational experience doing project management, design, installation, and procurement to fabricate and implement construction and mechanical solutions in a variety of industries. 10+ years of experience servicing environmental control systems including the regenerative thermal oxidizers (RTOs) for multiple applications. Provides project management and installation services.

Manuel (Manny) Sousa

Electrical Engineering Lead

30+ Years of electrical engineering experience focusing on providing integrated automated systems, providing controls/instrumentation, and doing industrial electrical supervision, programming, maintenance, and consulting. Experience in environmental, telecommunications, etc. industries. Provides special expertise with the Fluidized Bed Concentrator technology. Electrical Engineering degree from the Technical Institute of Viana do Castelo. Languages: English, Portuguese, and Spanish.

Partners

Environmental C&C Inc.

Environmental C&C’s fluid bed VOC (volatile organic compound) control and solvent recovery systems provide proven, cost-effective technology for industrial applications with high volume, low concentration flows of VOC's. This system can easily achieve flow volume reduction ratios of 1000:1 to as high as 10,000:1, allowing for several highly economical final treatment options. The high-volume reduction translates into low capital and operating costs compared with standard concentrator systems or direct treatment.

GOTECH Maintenance and Consulting

GOTECH focuses on integrating automating new systems as well as providing maintenance and consulting for existing environmental systems which it supports to present. This includes programming and providing systems for collecting data from industrial instrumentation, for Human Machine Interfaces (HMIs), etc. Applications include Fluidized Bed Concentrators, spray dryers, regenerative thermal oxidizers, solvent recovery systems, conveyors, percolators, distillation systems, flavor extraction systems, and many more.

Lachenmayr Construction LLC

Lachenmayr Lachenmayr Construction, LLC is a full-service General Contracting Company. We offer complete building services for your factory or business with consulting, project management, repairs and facility scale-ups. Architectural and stamped engineering drawings are also part of our expertise.

Customers

Summit Custom Spray Drying, Inc.

Summit Custom Spray Drying, Inc. operations provide efficient and effective processing of flavor, encapsulated fragrance, pharmaceutical, nutraceutical, light industrial, cosmetic, and animal feed ingredient products.

Spray-Tek, Inc.

Since 1981,

Spray-Tek has thrived by providing world class custom spray drying services to leading companies in the world's most quality-conscious industries. Working closely with our clients and trusted partners, Spray-Tek can take a project all the way from conception to commercial production.

Silgan Containers

As the largest provider of metal food packaging in the United States,

Silgan Containers is trusted by America’s most respected brands. Our reputation is based on a foundation of quality, excellence and unsurpassed technical expertise, enabling us to be a dedicated solutions-based partner to our customers.

Kirker Enterprises, Inc.

Since 1981,

Kirker Enterprises, Inc. has prevailed as a recognized leader in the development and manufacturing of the most innovative products since the 1940’s. Starting as a leader within the automotive coatings industry, Kirker Enterprises gradually shifted gears to enter the cosmetics segment to focus their business efforts on nail lacquer.

Contact Us

Corporate Headquarters & Service Center:

JS Technical Services LLC

32 Morganville Road

Matawan, NJ 07747

Phone: (732) 690-6298

Attention: James Starek